Design Note #47

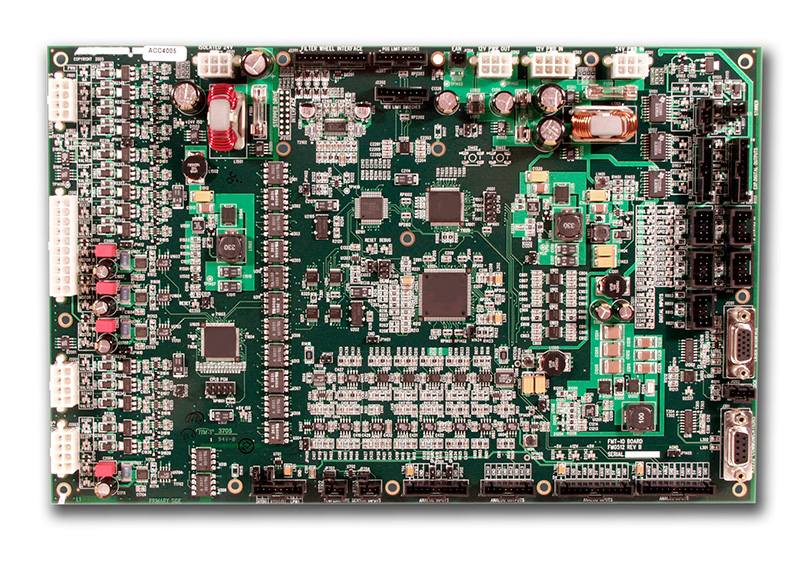

The coordination and integration of multiple, unrelated electronics is a daunting task. Multiple electrical interfaces together with connectivity, isolation, noise immunity, and precision operation made this instrumentation controller special. Working closely to understand the end application, we made certain that every facet of the design was covered – with contingency planning just in case we missed something.

Saving cost was paramount. Third-party stepper motor controllers are expensive, take up large amounts of physical space, and often have difficult power supply needs. OTEC implemented an embedded precision stepper motor controller on a single circuit board. Overall product cost was reduced, product integration was simplified and weight was successfully managed.

OTEC integrated the following features onto this single circuit board:

| • 4 Thermistor Channels | • 4 RTD Channels |

| • 4 Brush DC Motor Channels | • 1 Stepper Motor Channel |

| • 48 General Purpose IO’s | • 2 Low Noise Laser Power Supplies |

| • 4 PWM Heater Channels | • 4 General Purpose Analog Inputs |

| • 2 Timer Channels | • Non-volatile Parameter Storage |

| • Real Time Clock | • Daughter Board Expansion |

| • 1 RS232 Channel | • 1 RS422/486 Channel |

| • 4 Precision DAC Outputs | • 4 Valve Driver Outputs |

| • 1 USB Channel | • 1 Bluetooth Channel |

| • HiPot Isolation | • Agency Approvals |

The development of custom electronics technology solutions for our OEM clients is OTEC’s entire business. High-performance Instrumentation Design with rapid design cycles, demanding technical requirements, and unforgiving schedules set us apart. Contact OTEC today. We’ll put a custom instrumentation system in you hands tomorrow!