Design Note #35

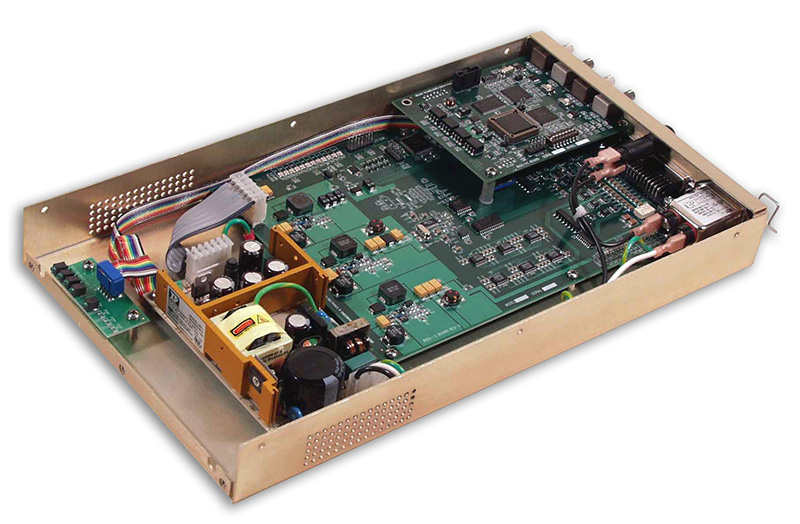

Varian Corporation hired OTEC to perform the cost reduction redesign of their precision Ion Implantation control system. With as many as thirty subsystems contained within a single Ion Implanter, the potential savings were tremendous.

The inside of Ion Implantation equipment reaches voltage levels in excess of 700,000 Volts above ground. Large ESD events are common in this environment. The new instrumentation subsystem had to achieve ESD immunity, while providing precision 20 bit analog input and output controls. Glitch-free operation in the presence of multiple ESD events was an absolute necessity.

High voltage immunity is achieved through dual, redundant optical communications links. Instrumentation and control information is relayed between the precision subsystem and the central control computing equipment over dual redundant optical links.

Careful circuit board layout techniques in which chassis ground planes, power ground planes, digital ground planes, and analog ground planes are split and routed with care is essential. Carefully crafted component placement, which takes into account energy discharge paths, means success.

The development of custom Electronics Technology solutions for our OEM clients is OTEC’s entire business. Industrial Controller Design with rapid design cycles, demanding technical requirements, and unforgiving schedules set us apart. Contact OTEC today, we’ll design custom industrial control electronics for you too!