Design Note #16

Today’s jet engines are a marvel of fuel efficiency. Keeping those engines operating at their peak performance requires constant maintenance. Turbofan roundness plays a critical role in jet engine performance.

Under typical use, jet engine component parts exhibit wear due to airborne sand and dust particles. These particles can erode an engine’s performance in surprisingly few operational hours. Frequent maintenance keeps an engine in peak condition. The ability to measure the roundness of the component parts of a jet engine assembly is critical to the unit’s fuel efficiency.

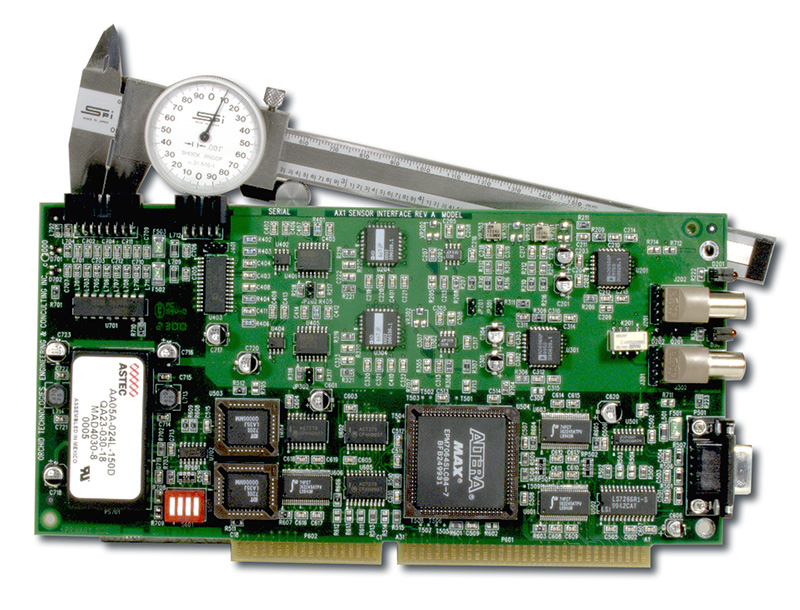

Using precision contact methods, OTEC performed the hardware design of a multi-channel roundness measuring device. Creating an architecture which supports an unlimited number of roundness channels, OTEC’s circuitry is capable of detecting roundness deviations of ten Microns or less in objects up to nine feet in diameter.

OTEC has performed many industrial instrumentation designs. Severe environmental stress and demanding performance is a typical requirement for OTEC’s instrumentation designs. Whether it’s vacuum, pressure, temperature, radiation, ionization, X-Ray detection, smoke detection, proximity, moisture, hydrocarbon, fuel combustion, or roundness—we’ve done it all. Contact OTEC today and let us perform an industrial instrumentation design for you too.