Design Note #84

OTEC was hired to perform the re-design of a recently obsolete industrial oven controller. Though the end application appears relatively simple, an industrial oven controller must perform a large number of real time monitoring and control functions. Industrial heating and conveyer belt systems generate an enormous amount of electrical noise. Ground-bounce, AC 50 and 60 cycle interference, transient noise, power drop-outs, and common mode noise are some of the elements of this electrically noisy environment. Challenging as this electrical environment is, OTEC’s MPC8308 based controller performs flawlessly – so that each and every piece is a perfectly appetizing work of art.

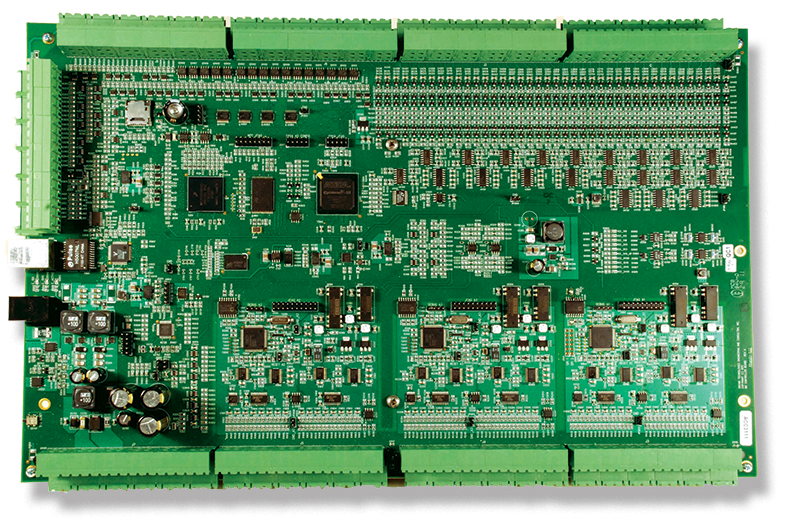

Industrial ovens typically have multiple zone heating systems. Temperature may be monitored with thermocouples, thermistors or RTD devices. Our MPC8308 based controller provides 48 channels of 24 bit low speed analog to digital conversion channels. Digital notch filtering removes unwanted 50 and 60 cycle noise. Each channel provides isolated inputs with two selectable full scale ranges of 50mV or 10V while operating within a large common mode noise environment.

Digital IO, quadrature counters, precision timers, and PWM output stages are supported for over 100 individual input and output signals. Altera Cyclone FPGA provides smart IO support thereby easing the real time requirements of the MPC8308 processor.

The development of custom electronic products for our OEM clients is OTEC’s entire business. The design of custom electronic products with rapid design cycles, demanding technical requirements, and unforgiving schedules sets us apart. Contact OTEC today!