Design Note #102

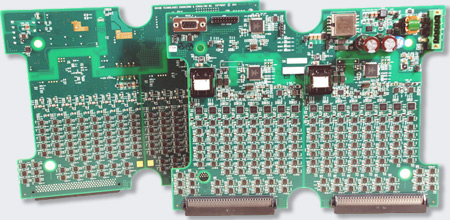

Hydrogen fuel cell technology provides clean, compact, high density energy for today’s demanding applications. Multiple fuel cells are stacked to generate surprisingly high wattage in very compact spaces. Real-time voltage monitoring of each individual cell in the stack is necessary to ensure proper operation. Stack voltages up to 250 volts are common. Up to four stacks may be combined producing a continuous 1000 volts at hundreds of amperes. OTEC designed this 256 channel, high precision fuel cell voltage monitor to operate in these demanding applications with proven operating temperatures from – 40 to + 125 degrees C.

Each hydrogen fuel cell produces approximately a one volt potential. Each fuel cell produces hundreds of amperes of current. At these normally high output current levels, small voltage differences from cell to cell matter. A few millivolts difference can be all that stands between proper operation and failure. The ability to rapidly and accurately monitor each cell’s voltage performs becomes a critical factor at start-up and during normal operation.

Continuous operation to 1000 volts is a demanding requirement. Custom magnetics with specially spaced windings, custom gapping, and well considered materials make all the difference. Kilovolt isolation for 1 minute is easy, kilovolt isolation for normal, continuous operation demands considerable design experience and know-how.

High speed megabit CAN Bus communications provides real time stack status. Statistical information is relayed to control systems over a single isolated CAN channel. Running on three Freescale K10 processors, OTEC’s non-preemptive Real Time Operating System provides safe, secure diagnostic, data acquisition and communications functions.

The development of custom electronic products for our OEM clients is OTEC’s entire business. The design of custom, precision, low noise analog systems with rapid design cycles, demanding technical requirements, and unforgiving schedules sets us apart.