Design Note #49

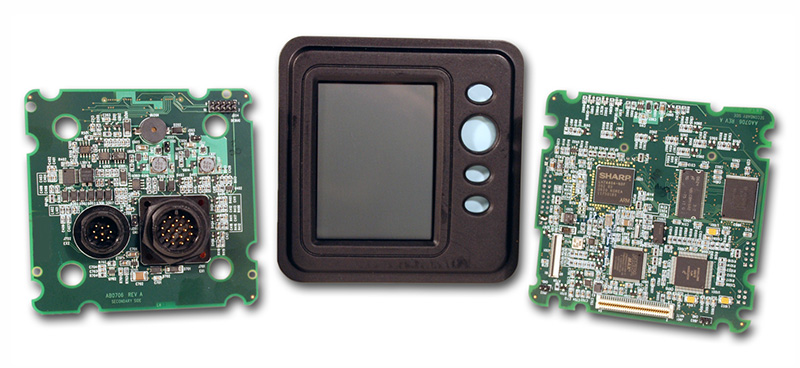

An ARM9 class processor and Window CE makes this marine engine controller ready for action. Real-time sensor processing integrates inputs from diverse sources such as paddle wheels, GPS Receivers, steering sensors, ballast sensors and CAN Bus high-speed engine sensors. A high-visibility color graphics LCD display provides operator visibility in both daylight and low-light conditions. A stylish low-cost, backlit keypad completes the package.

Operation in high-reliability, demanding marine environments was essential. High-quality, fail-safe operation necessitated careful circuit design and implementation. Low-power operation, hardened circuit design, cost-effective component selection and judicious component de-rating make up some of the high-reliability measures taken during system design.

High-contrast LCD Display is viewable in bright sunlight and low-light conditions. A customized, contrast enhancing AD-TFT electrical interface provides a high gamma display interface for increased readability. SVGA resolution makes this display ultra-clear. A rugged electrical interface system permits operation in high-vibration environments—perfect for the dash of a high power ski boat.

With only weeks until a major commercial boating trade show, OTEC was hired to develop both the hardware and driver software for this Windows CE- based ARM9 Marine Engine Control Product. Demanding marketing requirements dictated challenging electronic packaging requirements. Working around the clock, engineers at OTEC performed the simultaneous development of the hardware and software components. OTEC performed the entire electronic hardware and software driver design—delivering trade show-ready, functional prototypes six weeks after project start!

The development of custom Electronics Technology solutions for our OEM clients is OTEC’s entire business. High performance Custom Marine Electronics with rapid design cycles, demanding technical requirements and unforgiving schedules set us apart. Catch the wave. Contact OTEC today!