Design Note #71

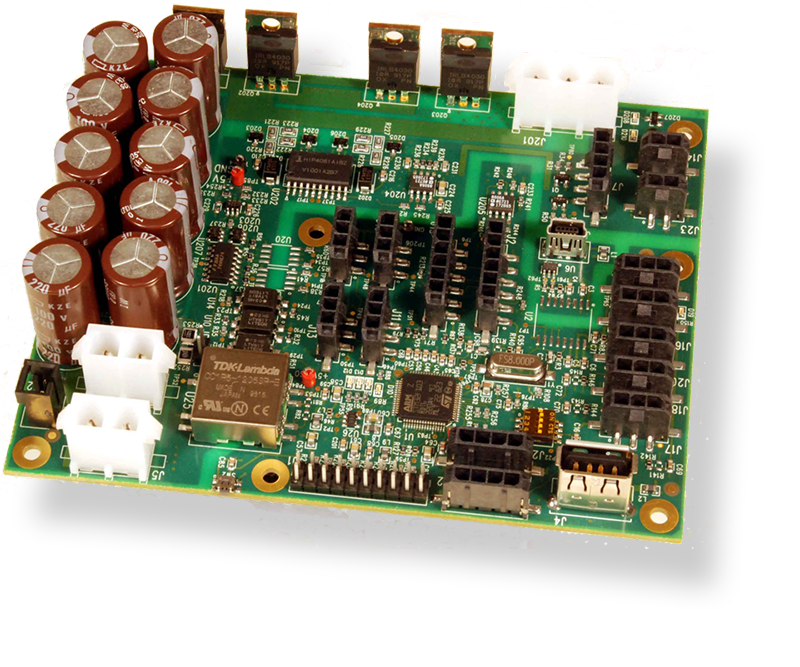

Robot arm motion control makes use of high current DC motors. These compact and powerful motors require low-cost precision-drive electronics. OTEC combined high-current drive electronics with powerful microprocessor technology to produce a cost effective motion control design.

OTEC’s newest motion controller design is based on ARM Cortex M3 and Cortex M4 processors. These low-cost, low-power 32-bit processors are revolutionizing the embedded computer world. Running at high speed, Cortex M3 and Cortex M4 processors are capable of performing both general computing tasks while simultaneously running the millions of floating point calculations needed to perform line sensing algorithms. Once exclusively performed by specialty DSPs, Cortex-M3 and Cortex-M4-based devices allow high-tech sensor design at low-end price points.

OTEC was called to redesign our client’s old 8051-based motion controller. With ten thousand new robot arms ready to ship, our client could no longer build motion controllers. OTEC’s role was to design a modern form-fit-function replacement for the old controller. Within six weeks we rapidly redesigned the controller’s hardware and implemented interface-level software that recognized the original control system command set. OTEC delivered initial working units in six weeks and first production units in ten.

The development of custom electronic products for our OEM clients is OTEC’s entire business. The design of custom motion control hardware and software with rapid design cycles, demanding technical requirements, and unforgiving schedules sets us apart. Contact OTEC today!