Design Note #58

OTEC was selected to update the electronics design of the Precision LCR Instrument shown below. Accurate to 0.05%, the original 1988 instrument design was well executed. However, vintage 1980’s state of the art electronic components were going ‘end-of-life’ at an alarming rate. OTEC studied the design and operation of the existing equipment. We generated a detailed development plan proposing significant technical improvements, and cost reductions. Then we set to work. Our new instrument is form, fit, and function compatible with the old, while achieving improved accuracy and a 3x increase in measurement speed.

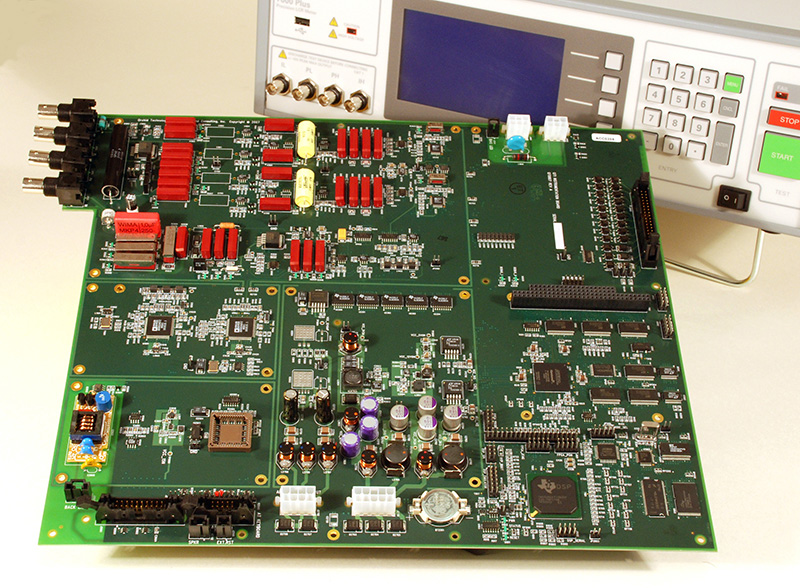

The original LCR meter required multiple circuit boards to perform its functions. These circuit boards were shielded with a complex jumble of sheet metal, spacers, and screws. Additionally, expensive coax cables were installed to make the DUT connection. OTEC’s new design is elegantly simple. All circuitry is now on a single board, Altera FPGA devices integrate digital functions, and system shielding has been simplified. The result—a lower cost, easier to build, easier to service assembly that has another five to seven years product life.

Low total-harmonic-distortion precision sine wave generation, phase-balanced analog amplifiers, low noise power systems, and very high accuracy 18 bit analog to digital conversion circuitry were our design challenges. A Texas Instruments TMS320C6713B performs high speed floating point calculations in support of the measurement functions.

The development of custom electronic products for our OEM clients is OTEC’s entire business. The redesign of high performance instrumentation with rapid design cycles, demanding technical requirements, and unforgiving schedules sets us apart. Contact OTEC today!