Design Note #125

Hydrogen fuel cell monitoring hardware continuously scans the health-status of individual hydrogen fuel cells in operation. Producing roughly one volt each, individual fuel cells are operated at high current in series. Individual fuel cells are combined into a stack. OTEC’s latest fuel cell monitor is capable of monitoring the real-time status of up to 288 individual fuel cells within a stack. Programmable alarms provide real-time safety status.

High speed CAN Bus communications provides individual cell status and alarm conditions to upper level engine controllers. High speed CAN Bus communications allows message prioritization, multi-drop distributed communications, positive message receipt confirmation, and CRC-based message error detection protocols. High speed CAN Bus communications provides a secure, error free means of communicating critical operating information.

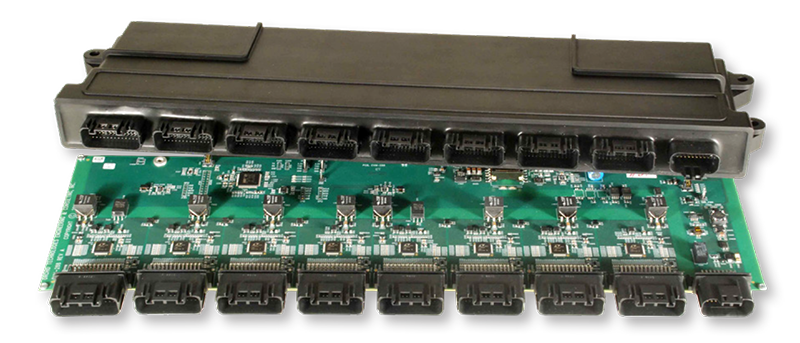

Operating in wet or humid environments, fuel cell monitoring hardware must withstand severe environmental conditions. OTEC’s custom designed IP68 rated injection molded enclosure provides an environmentally secure one-piece packaging solution. Coupled with a custom potted front panel and internal selective conformal coating, the sensitive analog electronics are well protected.

STM32 ARM-M4 provides the micro-processor monitoring function. Running OTEC’s proprietary non-preemptive real time operating system, fuel cell data acquisition and processing are accomplished in real time. Small and efficient, OTEC’s proprietary non-preemptive real time operating system securely performs safety-critical tasks.

The development of custom electronic products for our OEM clients is OTEC’s entire business. The design of high performance fuel cell monitor hardware and custom injection molded enclosures with rapid design cycles, demanding technical requirements, and unforgiving schedules sets us apart. Contact OTEC today!