Design Note #85

Large HVAC systems exchange air between the inside and outside of a building. In hot weather, cool air is expelled and warm air is drawn in. The reverse is true when the weather changes. Rotating heat exchanger wheels provide a means to recover energy in an HVAC system by pre-cooling intake air in hot weather or pre-heating intake air when the weather cools. High reliability drive systems are essential to the long term life of the energy recovery system. OTEC’s new linear DC motor drive controller provides greater than ten year operational life in demanding, dirty environments. Replacement of old-style belt driven systems increases reliability while reducing the energy spent in operating the energy recovery system itself.

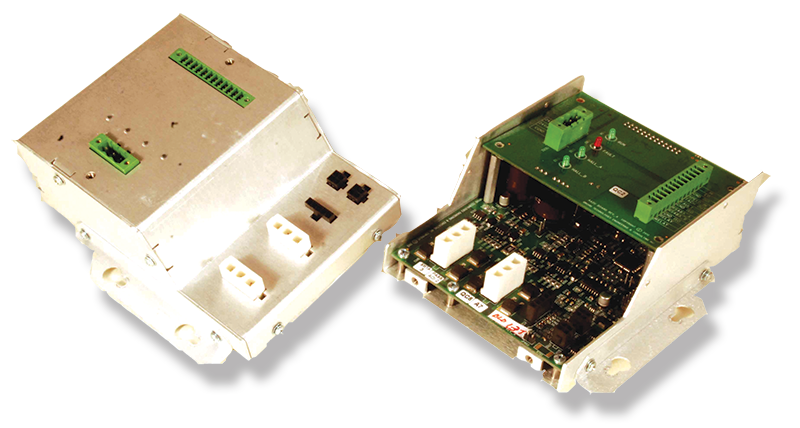

Magnetics mounted on the rim of the rotating machinery is driven by electromagnets mounted on the machinery’s frame. This arrangement creates a low-cost, powerful, linear DC motor. Hall sensors provide commutation information while digitally modulated PWM drive electronics provides variable energy to the motor system. Microcontroller software provides PI drive algorithms to realize constant angular velocity control. The linear DC motor drive is scalable and well suited for driving small to very large rotating machinery with high inertial properties.

Firmware running on an NXP1754 ARM Cortex-M3 microcontroller provides the brain of the linear DC motor drive. Sized for expansion, motion control firmware occupies about half the microcontroller’s code space. Network communications, advanced diagnostics, error controls, manufacturing diagnostics and sensor systems occupy additional code space.

The development of custom electronic products for our OEM clients is OTEC’s entire business. The design of custom electronic products with rapid design cycles, demanding technical requirements, and unforgiving schedules sets us apart. Contact OTEC today!